jatropha oil extraction process

Leading the way in Jatropha Research, Innovation, and Sustainability

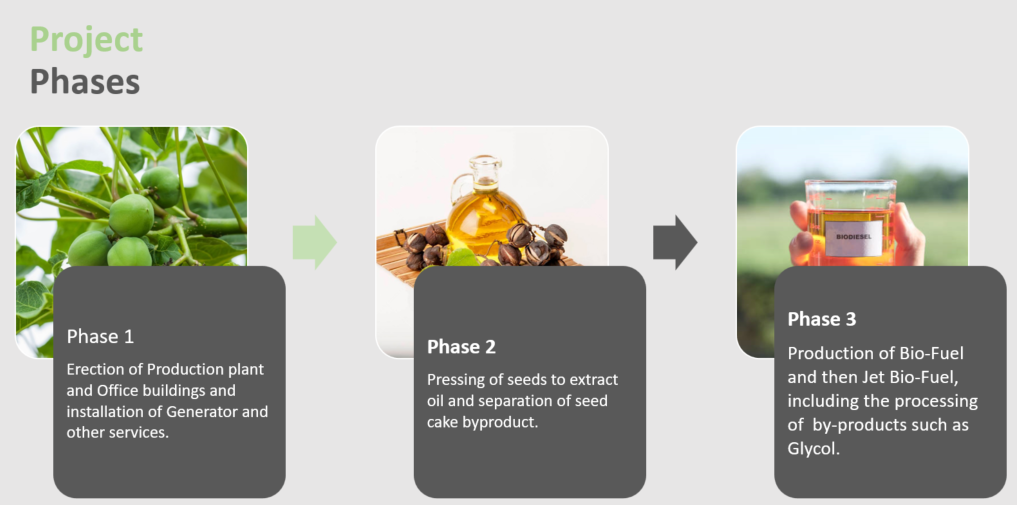

The process after a Jatropha plant has been picked involves several steps to extract and utilize the valuable components, particularly the oil from its seeds. Here's a general outline of the process:

1. Harvesting:

2. Seed Extraction:

3. Cleaning:

4. Drying:

Jatropha plants are typically ready for harvesting when the seeds turn dark brown and begin to fall from the plant. Harvesting is done by hand or through mechanical means.

The harvested seeds are separated from the rest of the plant material. This can be done manually or using machines designed for seed extraction.

The extracted seeds undergo a cleaning process to remove impurities such as dirt, leaves, and other debris. Clean seeds are essential for the quality of the subsequent processes.

The cleaned seeds are dried to reduce moisture content. Drying is crucial to prevent the growth of mold and ensure the seeds are suitable for storage and further processing.

5. Storage:

6. Oil Extraction:

7. Refining:

8. Biodiesel Production (Optional):

Dried Jatropha seeds are stored in a cool, dry place to maintain their quality. Proper storage conditions prevent the seeds from deteriorating and protect them from pests.

Jatropha plants are typically ready for harvesting when the seeds turn dark brown and begin to fall from the plant. Harvesting is done by hand or through mechanical means.

Jatropha plants are typically ready for harvesting when the seeds turn dark brown and begin to fall from the plant. Harvesting is done by hand or through mechanical means.

Jatropha plants are typically ready for harvesting when the seeds turn dark brown and begin to fall from the plant. Harvesting is done by hand or through mechanical means.

12. Byproduct Utilization:

13. Waste Management::

11. Quality Control:

12. Packaging and Distribution:

The byproducts of the oil extraction process, such as Jatropha seed cake, can be utilized as organic fertilizer. It is rich in nutrients and can contribute to soil improvement.

Any waste generated during the processes, such as husks or residues, should be managed responsibly. This may involve composting, recycling, or other environmentally friendly disposal methods.

Throughout the entire process, quality control measures are implemented to ensure that the final products meet industry standards and are safe for u

The final products, whether it’s Jatropha oil or biodiesel, are packaged appropriately for storage and transportation. They are then distributed to end-users, industries, or markets.

By following these steps, the journey from a freshly picked Jatropha plant to valuable end-products is completed, showcasing the plant's potential in sustainable energy and various industries.

Drone Flight of the Jatropha Plant Fields

Now Plants from the Nursery Ready for Planting

First Drop of Jatropha Oil

Jatropha Plant just been picked

Left is our bio Fuel after Transesterification

Right is Oil processed form our seed